In order to ensure food safety and maintain quality, biological and chemical reactions that cause spoilage should be controlled. For this reason, thermal (thermal) processes (pasteurization, sterilization, etc.) are applied during the industrial production and processing of food. However, these techniques can cause the loss of nutrients responsible for the nutritional value of the food and various undesirable changes in sensory properties. New generation food preservation techniques are one of the most important studies in recent years.

For this purpose, today, food manufacturers have sought new technologies and methods in order to both extend the shelf life of the food and protect the nutritional quality of the food. In a period when environmental sensitivities are accelerating in line with the current climate crisis symptoms, non-thermal technologies are a promising field of study, especially with their costs that have started to decrease recently. With the increase in the flow of information on these applications and the understanding of the savings provided by the company in the long-term energy item, it is possible to create a natural and fresh consumption opportunity in the related foods, both by microbial inactivation and by minimizing the quality defects mentioned [1].

New Techniques Alternative to Heat Treatment

• Ultrasound

• Irradiation

• Emphatic Electric Field

• High Hydrostatic Pressure

• Ohmic Heating

• Ultraviolet Light

• Microfiltration

• Osmotic Drying [2]

1.1. Pulsed Electrical Field (PEF)

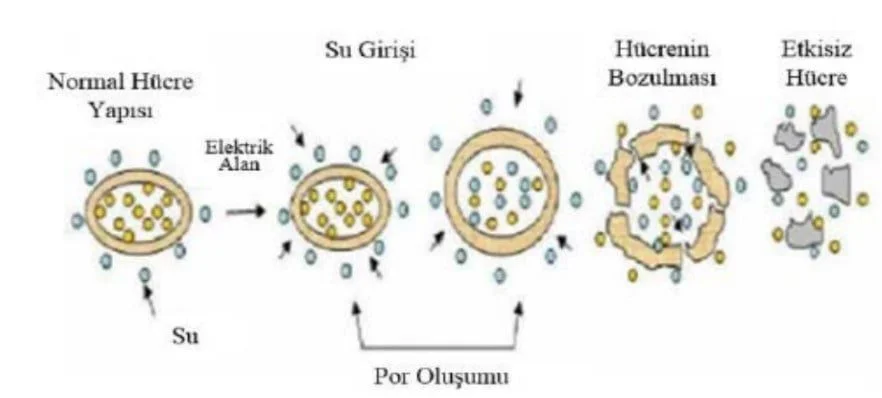

The accent electric field technique is carried out by applying a high voltage (10-80 kV/cm2) for a short time (1-100 µs) to the foodstuffs placed between 2 electrodes. The effectiveness of the process depends on the electric field strength, the shape of the pulse, the number of pulses and the application time.

The basic principle is the destruction of the lipid and protein structure of the cell membrane, which is exposed to stressed electrical impulses (electroporation), and the acquisition of the targeted compounds. In this way, pasteurization of juices, yoghurt, soups and liquid eggs; It is possible to increase the productivity of fruit/vegetable juices, to preserve the color properties naturally, and to store carotenoid, vitamin C, phenolic and antioxidant compounds in the structure [4]. It is one of the most common techniques among the new generation food preservation techniques. The German company “Elea” is one of the most important manufacturers.

1.2. High Hydrostatic Pressure

In the high hydrostatic pressure process, the water surrounding the sample is compressed by pressure between 100-1000 MPa and accompanying low-medium temperature (10-60°C) to preserve the food. Thus, in the food industry, beverages, fruit-vegetables and their products (juices, jam, avocado products, apple puree, etc.), meat products (cooked and dried ham), seafood, fish, ready meals, instant soups, yoghurt, salad dressings A wide range of foods such as oysters and oysters can be made durable [2]. For example; In a study on the application of YHB to traditionally produced boza samples at 150, 250, 350 MPa pressures, at 5°C and for 5 minutes, it was found that the combination of 350 MPa 5°C 5 minutes parameters reduced the bacterial load in boza by approximately 3 logs, and yeast and molds were reduced in all samples. It was determined that it was completely destroyed (Ilgaz, 2014). It is among the most preferred new generation food preservation techniques in the industry.

1.3. Ultrasound

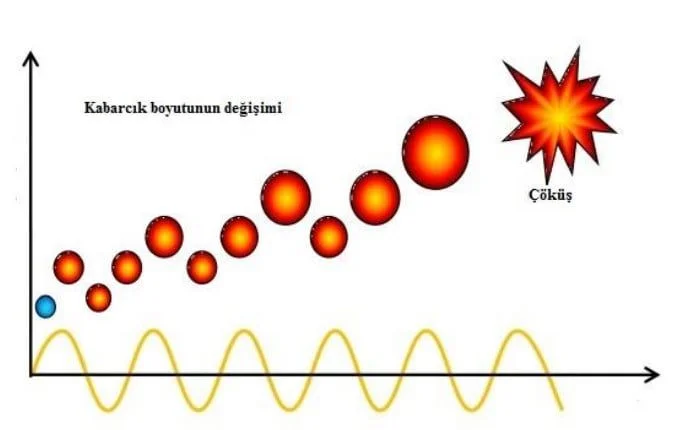

Sound waves with frequencies between 20 kHz and 10 MHz that the human ear cannot hear are called ultrasound. The basic mechanism of action of ultrasound is cavitation. Cavitation; It is an important effect that occurs when microbubbles in liquids reach critical size and burst. Ultrasound in the food industry; Unattended monitoring of the production process, determination of air bubbles in aerated foods, determination of fat content in meat, characterization of fruits and vegetables, determination of the quality of eggs, surface cracks in cheese, texture of biscuits, milk coagulation, control of wine fermentation, characterization of dough, different physicochemical properties such as sugar content and acidity. It is used to determine the properties [3][4].

1.4. Ultraviolet Light

The basic principle of the UV lamp is to inactivate the electromagnetic UV-C rays with a wavelength of 200-300 nm, located in the ultraviolet (UV) region between visible light and X-rays, by taking advantage of their lethal effect on microorganisms. In general, UV-C rays do not have any negative effects on foods when used in required doses. However, UV-C rays can cause the formation of free radicals in foods, damage to vitamins and proteins, oxidation of structures, discoloration, and loss of flavor and aroma substances. Therefore, for the correct exposure of foods to UV-C rays, it is essential that the light limits specific to food groups have been determined and optimization studies for these foods have been completed.

In addition to reducing the microbial load of foods, UV rays can also be used for decontamination of equipment surfaces, air, water and packaging materials (box, bottle, cardboard, tube, film and foil, etc.) in food enterprises (bakery products, cheese and meat producing enterprises, etc.). [2].

1.5. Irradiation

Food irradiation is one of the relatively new techniques that allows to extend the shelf life of foods by damaging the genetic material (DNA) of microbial entities. In the food industry, irradiation can be used to reduce microbial load, provide sterilization, delay ripening, prevent insect and parasites in dried or fresh fruits and vegetables, cereals, nuts, oil seeds, legumes, spices, herbal teas, poultry meat, red meat, fish and seafood. It is used for various purposes such as the control of infections. In addition, sprouting can be prevented in tuber foods such as potatoes and onions.

In 1997, the commission formed by the stakeholders of the “World Health Organization” (WHO), “Food and Agriculture Organization” (FAO) and “International Atomic Energy Agency” (IAEA) stated that irradiation is a safe and effective method when used in the dosages stipulated for the specified product groups and accepted that food preserves its nutritional value [1].

1.6. Ohmic Heating

In this method, the food is heated by using the resistance it applies against the electric current passed through it. Ohmic heating is a volumetric heating method. Electrical energy transforms into heat, providing a fast and homogeneous heating, and the entire food comes into contact with heat at an equal rate.

Ohmic heating can be used for liquid products, liquid products containing particles (soups, stews, syrups, fruit slices in syrups) and heat sensitive foodstuffs. Especially in protein-containing food products, pasteurization can be done without denaturation of the protein (without deteriorating its structure) and without coagulation. In addition to preserving food products, opening frozen products, peeling fruits and vegetables, accelerating drying and extraction processes are among the potential uses of the method [5].

Click for more information about New Generation Food Preservation Techniques

2. Bibliography

[1] https://acikders.ankara.edu.tr/mod/resource/view.php?id=83049 (Access date: 25.07.2022)

[2] Güven, E., Yıldız, H. (2016). Industrial Applications of New Non-Thermal Food Preservation Techniques-1. FOOD, 41(4): 235-242.

[3] Güven, E., Yıldız, H. (2016). Industrial Applications of New Non-Thermal Food Preservation Techniques-2. FOOD, 41(4): 243-250.

[4] Karabacak, A. Ö. (2015). Effects of non-thermal processing methods on food components. Uludag University Institute of Science and Technology, Bursa.

[5] https://e-dergi.tubitak.gov.tr/edergi/yazi.pdf;jsessionid=XhRU0GWbhVfbfMhbyF7bG0-R?dergiKodu=4&cilt=42&sayi=642&page=60&yaziid=28317